Compactors are there to

help you organize your waste in an efficient manner. If you’re using a trash

compactor in your company’s back room or warehouse, then you’ll be familiar

with just how useful these machines can be for businesses that struggle to eject

and store waste in a fashion that’s kind to the environment, healthy for

workers, and efficient in a business sense. This article will show you how to

extract the best value from your compactor, by observing simple but important

practices that’ll guarantee your optimal waste disposal for years to come.

Beware Liquids

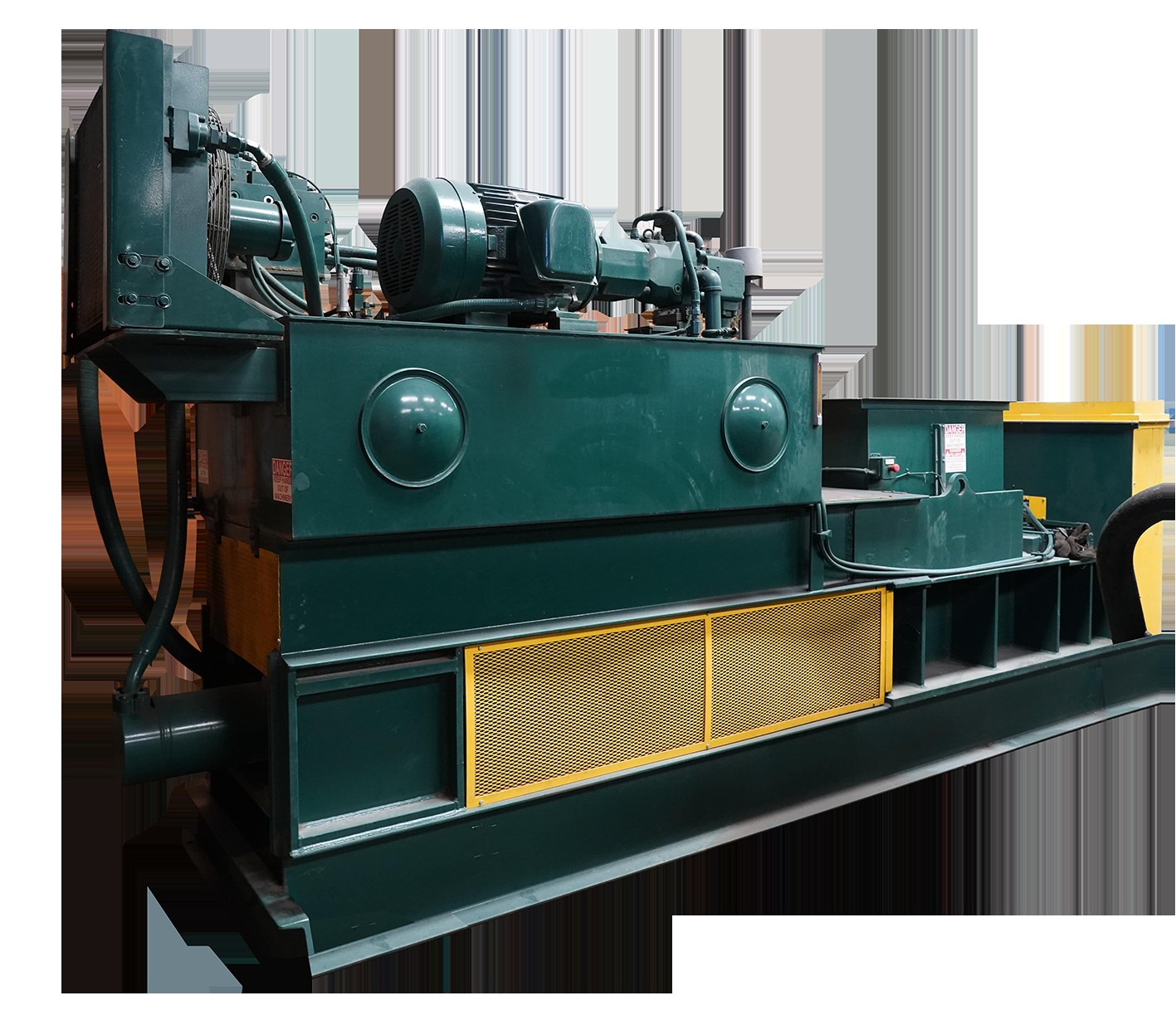

Compactors are generally used to crush and compact a wide array of trash, from the waste food groups that you might need to dispose of in a food superstore, all the way through to the metal, plastic and materials that can be part of the waste process in industrial production.

Now, while compactors are made to last, it’s best to empty liquids before you load them into your compactor. Why? Well, because they’ll soak all the way through your compacted trash before dropping onto the surface underneath your baler. As your compactor is heavy and difficult to move or clean beneath, you’ll end up with a stink of dried liquids that your company would really rather do without.

Regular Checks

All businesses should put an individual in ultimate charge of their machinery – someone with an engineering background and the ability to make quick and accurate assessments of the machinery that is used inside the business. This same rule goes for compactors – have someone in your company check the status of balers frequently in order to avoid the negative consequences and costs of baler breakages.

Service History

Is your baler new or used? Will it have an issue in the coming months, or is it expected to last for years without so much of a hiccup? Clearly, the status of your baler is important, as an out-of-action baler in a business that produces lots of waste every day can create a horrific log-jam of trash that can take weeks to properly clear. Remain on top of your baler or compactor’s service history, and check-up requirements, in order to avoid this damaging scenario.

Develop Processes

Finally, the most effective businesses will develop processes either side of their compactor’s mechanism in order to make their entire waste disposal system as efficient and streamlined as possible. What this means is that waste management is seen as a system that passes through your compactor and onto the trash collection trucks that eventually take away your trash – at a cost, of course. By ensuring that you’re compacting right, and sorting your trash on either side of the compaction moment, you’ll be able to ensure the cubes of trash you produce are optimally crushed, and that you’re always seamlessly getting rid of your trash as soon as it’s created – helping you make time and space for more important business processes.

These tips will help you get the most out of your company’s compactor.